Ideas for the pursuit of excellence are game-changers that push an organization to the next level. Organizations operating in any industry can benefit from expanding their focus from quality assurance—institutionalizing incremental improvements in degrees of excellence—to the overarching pursuit of comprehensive excellence. One way to support excellence is to ensure that the architecture/engineering/construction (AEC) infrastructure in which a business operates integrates with the business process workflow. The interface between technology and the AEC infrastructure has begun a radical change that will enable an entirely new approach to creating and managing workspaces.

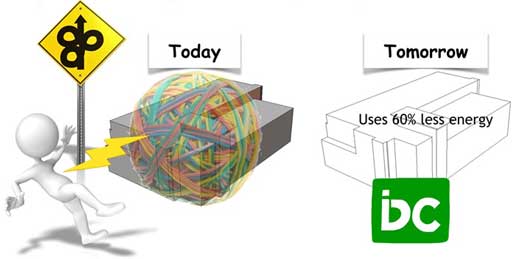

Buildings of the future will respond to enterprise workflow needs with the nimbleness of today’s enterprise information technology infrastructure, mirroring the evolution from mainframe/terminal rigidity to cloud/mobile flexibility. There is a fascinating panoply of ideas to explore around applying intelligent DC technology (iDC) to reinvent the interface between AEC infrastructure and enterprise workflow. There was abundant research on iDC in the early 1990s that did not emerge into the market, in part because the technology to implement iDC was then too immature to be cost-effectively applied. Today, iDC is ripe for exploitation.

Excellence ∝ Workflow Efficiency and Effectiveness

Enterprise workflow is the total flow of functional operations—conducted by people, computers, machines, or building infrastructure—that allow an entity to execute its mission. Workflow encompasses the systems and processes that provide the optimal path to success as well as the interactions and relationships among them. Efficient and effective workflow is a prerequisite to excellence.

New technologies allow workflows to be modeled in much greater depth and detail than has been done to date. Traditionally, information models were built to describe single entities—for example, a building information model (BIM) describes the building fabric. To support workflow optimization at an enterprise or higher level, the information models must be layered to encompass multiple entities, their respective workflows, and the interaction among workflows. Advances in computing and communications technologies now allow the AEC infrastructure interface to be integrated as a layer in the enterprise workflow model.

This offers the opportunity for players in the AEC industry to move from a posture of selling a commodity on the open market (at a 4% gross profit) to partnering with customers to provide customized flexible AEC infrastructure services that support customers’ pursuit of excellence (at professional services industry gross profit of ≈40%). To do this successfully, the AEC industry must learn to view its “product” through the eyes of the customer.

Defining Success | Excellence

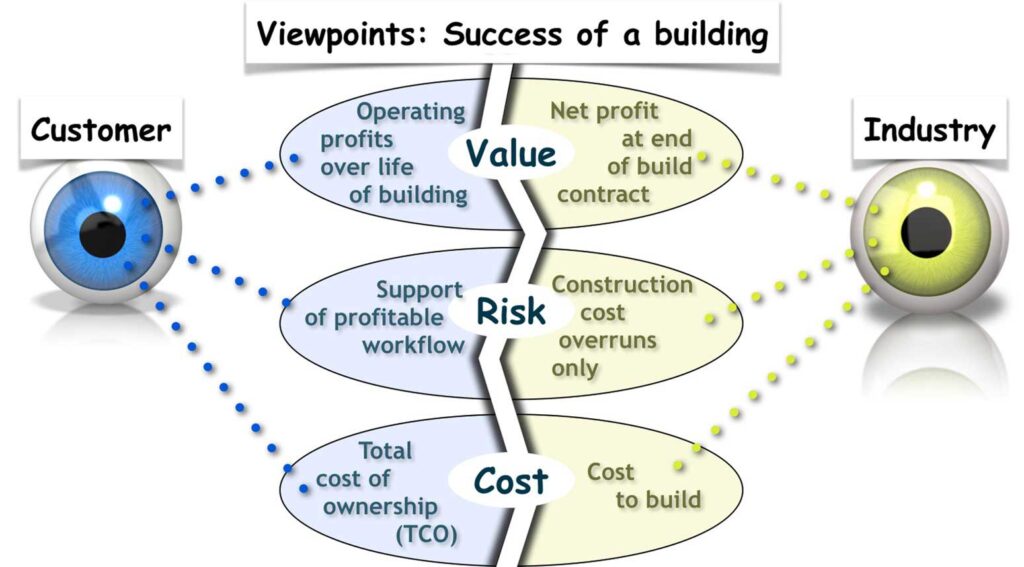

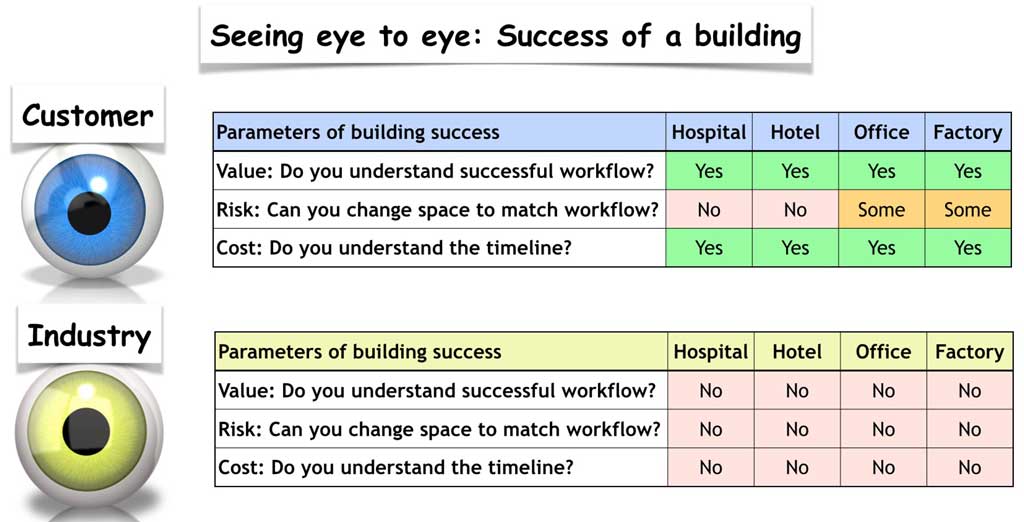

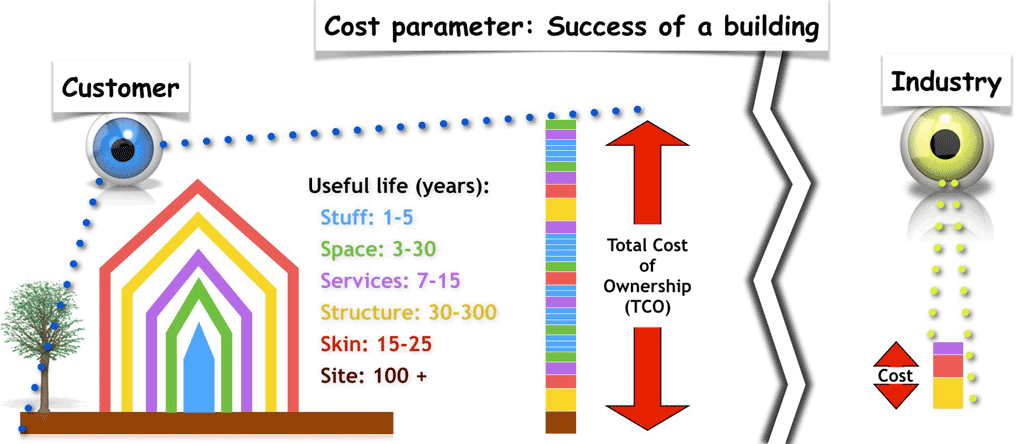

How do we define the success of a building? We can perhaps all agree that the goal “success of a building” is achieved through increasing value while lowering risk and cost. But if we delve more deeply into what constitutes value, risk, and cost from the customer perspective versus what constitutes value, risk, and cost from the industry perspective, we begin to see a divergence. The AEC industry has traditionally had a time-limited perspective, bounded roughly by the signing of the contract and the certificate of occupancy. But the customer measures success in terms of total cost of ownership and total usability over the life of the building. The builder computes success over the length of the contract to build; the customer computes success over the lifetime of the enterprise operating in the building.

At the beginning of the 21st century, the AEC industry fell in love with the design charrette as a technique for consulting with “stakeholders” about their needs. As a proxy for truly driving design from the customer’s viewpoint, charrettes were usually too little, too late, and too superficial. At the end of the design charrette, the AEC team typically walked away with a list of building features to be incorporated into the design and no more understanding of how the customer understands the parameters of building success than when they walked in.

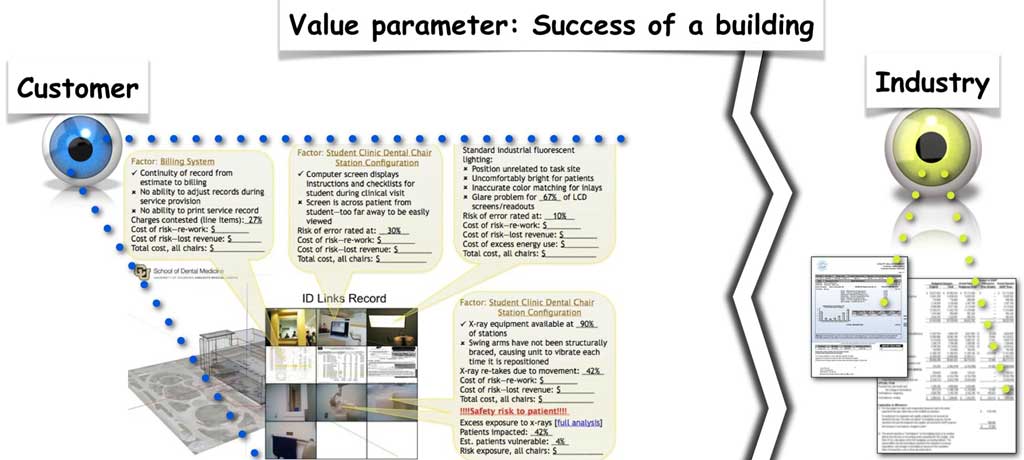

The Value Parameter

Many studies have been conducted in the past century to explore the implications of this disconnect, but the post-industrial AEC industry continues to draw the line of its involvement at the certificate of occupancy. In doing so, they throw away an opportunity to add value to a customer’s business—and be compensated for it. A 2005 British Council for Offices (BCO) study estimates that enterprise costs for building construction, building operation, and staff salaries are in the ratio of 1:1.5:15. In other words, the lifetime total cost of operating a building is one and a half times the amortized cost of construction, and staff salaries for operating the enterprise in that building are 15 times the amortized cost of construction. This leads to the conclusion in another BCO paper that a 2% to 5% increase in staff productivity can cover the total cost of providing their accommodation. Taking the analysis a step further, a 2005 whitepaper by the international design firm Gensler estimated better workplace design could increase employee productivity by 19%.

Consider, for example, how success of a building’s indoor environmental quality is defined. The AEC industry looks at energy efficiency of the HVAC and lighting systems as the measure of success; the customer looks at employee productivity as the measure of success. In a 2004 conference presentation, a Cornell University researcher reported that when the office temperature in an insurance company office was increased from 68° to 77° F, typing errors fell by 44 percent and typing output jumped 150 percent. But a 1931 New York Commission on Ventilation experiment (cited on page 4 of Glen I. Earthman, “School Facility Conditions and Student Academic Achievement” (2002)) determined that the optimal air temperature in classrooms was 68°-73° F. Even earlier workplace studies found that when work involved physical labor, 68° F was optimal and productivity dropped 15% at 73° F and 28% at 86° F. Three things leap to the eye from these studies: 1) ambient temperature influences productivity, 2) the optimal ambient temperature varies according to the workflow being performed, and 3) non-optimal temperature in a work environment directly impacts the bottom line.

Recently, we had occasion to observe a sterling example of the disconnect between the AEC perspective and the customer’s perspective. A dental clinic moved into a brand new, state of the art building with UV blocking, tinted, inoperable windows and low energy consumption fluorescent lighting. Patient satisfaction plummeted and re-work skyrocketed for one workflow in particular: the application of veneers—because of the artificial lighting conditions it was impossible to correctly match the color of the veneer applied to a cracked tooth to the healthy natural teeth next to it. To the AEC contractor, the energy savings meant success; to the customer, the design meant increased costs and lost revenue—failure.

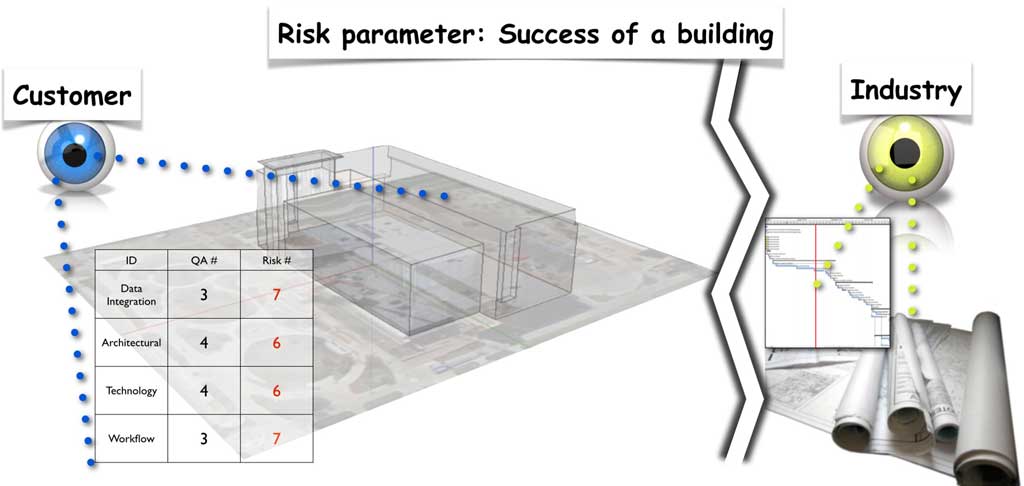

The Risk and Cost Parameters

We have discussed in some detail how, with respect to value, the builder computes success over the length of the contract to build and the customer computes success over the lifetime of the enterprise operating in the building. Building on that discussion, we can touch more briefly on the distinctions in perspective with regard to risk and cost

The OED defines risk management as the forecasting and evaluation of financial risks together with the identification of procedures to avoid or minimize their impact. Textbooks may add that “evaluation” encompasses identification, assessment, and prioritization. The AEC contractor looks at the risks inherent in the time-limited process of construction, and the customer looks at the risks that threaten the achievement of excellence in its industry every day that it operates.

To the customer, the AEC infrastructure is only one of several sources of risk. Current interfaces between technology and the AEC infrastructure provide information that can help the building owner forecast and perhaps control expenditures for maintenance and utilities. They contribute a small amount to the customer’s ability to manage one aspect of one source of risk. But, as we saw in the discussion of value, managing expenses does not always translate directly into increased return on investment (ROI). Indeed, if the result is decreased productivity, then expense management has become a risk to the achievement of both excellence and profit. Penny wise and pound foolish, anyone?

The time-limited nature of the AEC perspective is even clearer when we look at the cost parameter. Many AEC contractors pay lip service to a longer term view of cost by incorporating components such as low maintenance finishes and low energy or water consumption fixtures. Some are even able to demonstrate the calculations behind the rule of thumb that for every dollar skimped in construction, the occupant will spend $10 additional each year on maintenance. But the truth is that over the 30 to 300 year life of a structure, the total cost of ownership will include 10 to 20 re-designs of the interior space, four to 20 replacements of the entire wiring, plumbing, and/or HVAC infrastructure, one to six renovations of the building façade, etc. The proliferation of cubicle farms is one way in which building owners acted to mitigate the financial risk of repeated rearrangements of interior space—but this technique may not be appropriate for all workflows.

Buildings of the Future: A Joint R&D Venture, c. 1992

In the early 1990s, a group of R&D departments for various AEC industry sectors, the Navy, and the reinsurance branch of Lloyds established a joint venture to explore how buildings of the future could be designed and built to bridge the gap between the AEC industry’s perspective and the customer’s perspective. The participants recognized that if they could expand the concept of AEC infrastructure to include a cyber interface that could measure and optimize the success of the building and its AEC infrastructure in supporting, even improving, the customer’s operational workflow, they would all benefit. The benefit to the customer was obvious, but at the same time AEC participants could break free of the commodity-type margins that were about to become the norm in the industry and insurers could quantify risk in ways that would dramatically improve loss forecasting. Of course, in the 1990s, this was not conceptualized as a “cyber interface:” the Internet of Things (IoT) was not yet envisioned, supercomputers were required to run parametric models, and web-based management dashboards were the stuff of science fiction.

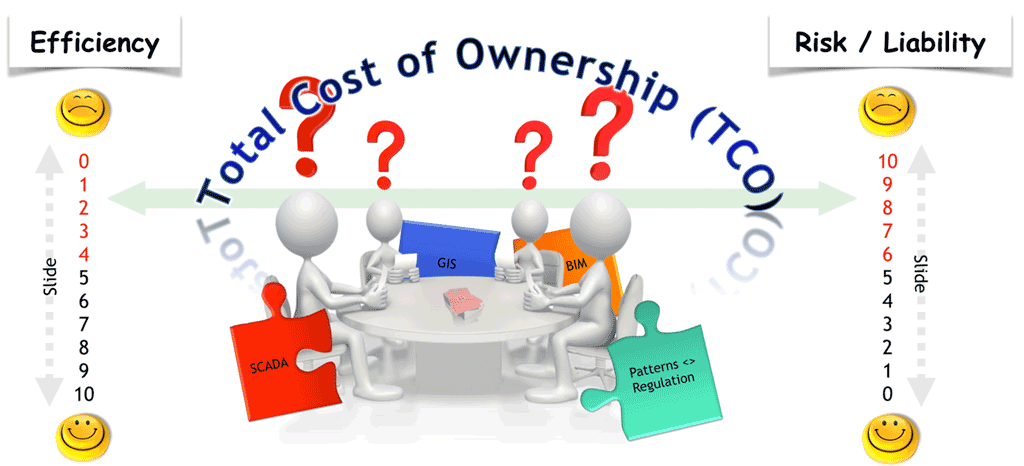

The participants looked to industrial AEC for a model. Power, petrochemical, and other large industrial plants were (and had been for a while) using SCADA to approximate what would eventually become IoT. In exploring how to evolve industrial SCADA controls into a workflow-linked management dashboard, the advantages of iDC began to emerge as a critical research topic.

- Project: Buildings of the Future

- Purpose: Look at how buildings are constructed and utilized and find dynamic ways to revolutionize building design

- Findings: To really revolutionize buildings we need to:

- Look at what goes on inside the building, not just the building structure

- Understand client workflow

- Enable modular workspaces to support tasks

- Understand total cost of ownership on the client’s timeline

- Method:

- Build prototype buildings for clients in different sectors and test technologies and designs

- Build code-independent structures inside a code-compliant warehouse

- Two identical buildings for each sector: one DC, one AC

- Measure client view of building success using real workflow scenarios

- Sectors:

- Hospital

- Hotel

- Office

- Factory

Reliance on AC power requires embedded, complex tangles of fixed wiring to carry 440/220/110 volt streams throughout a building. Each voltage needs its own wiring net, all entrapped inside the structural fabric for safety. What could be dimly foreseen in the 1990s, and has become a matter of course today, is that most of the equipment required to execute the workflow is computer-controlled, and computers use low-voltage DC power. From data rooms to desktops, today’s workplace is littered with “transformers” (AC to DC converters)that both step down the grid’s AC voltage and convert it to the DC power required by the equipment into which they are built or to which they are attached.

The power grid’s reliance on AC transmission and distribution evolved in response to the limitations of the earliest electrical technologies. High-voltage AC power can be transmitted with far lower distribution losses than DC power. Transformers step power up for transmission (high voltage lines carry power stepped up to hundreds of kilovolts) and step it down at the point of distribution. This makes it more economical to use remotely located generators and distribute power over long distances. This system has served the power industry well, and it has spawned a very complex regulatory and building code environment designed in part to ensure healthy returns on industry investment in long-distance distribution. The “Buildings of the Future” R&D project tried to envision ideal power provision from an end-user perspective, without the constraints of current practice, code, and regulation.

DC-powered lighting and equipment operate at much lower voltages than the AC current running through conventional wiring. A 12/24/48 volt DC feed can be run through a simple flexible ribbon that requires far less shielding than current AC feeds. A building could be equipped with an ubiquitous, modular, low voltage electrical wiring grid to which any DC-powered device could be attached anywhere at any time by anyone.

From the customer’s perspective, such a system would up-end the conventional understanding of total cost of ownership of a building. Reconfiguring the interior space would be enormously simplified—and the cost of adapting the building to changing workflows commensurately reduced. Further, if the system were to be configured as an intelligent system that delivered current only on demand and returned feedback on the efficiency of operation of the building and the workflow, the building itself could become a contributor to increasing the efficiency of every workflow, achieving excellence, and increasing profit—with a commensurate reduction in risk and liability.

Quality assurance programs such as Lean deliver incremental improvements in the efficiency of processes by looking at the details of individual processes. It is a cliché of QA that process failure largely originates in the handoff, that space between steps where control passes from one actor to another. A really good quality assurance program looks at handoffs between as well as within processes, understanding that good outputs depend in part on good inputs.

A pursuit of excellence program looks at the enterprise as a complex organic whole. From that perspective, the building can be seen as the exoskeleton of the organism, as integral to its ability to pursue excellence as the cash flow that is its bloodstream. The increasing popularity of integrative health care testifies to our increasing understanding of the importance of the interrelations and interdependencies among the multiple systems of the human body—cardiovascular, nervous, digestive, endocrine, muscular, respiratory, skeletal, etc. It is possible to achieve good quality of life when individual systems are treated in isolation, but excellent health depends on all systems being healthy both in themselves and in their relationships with each other.

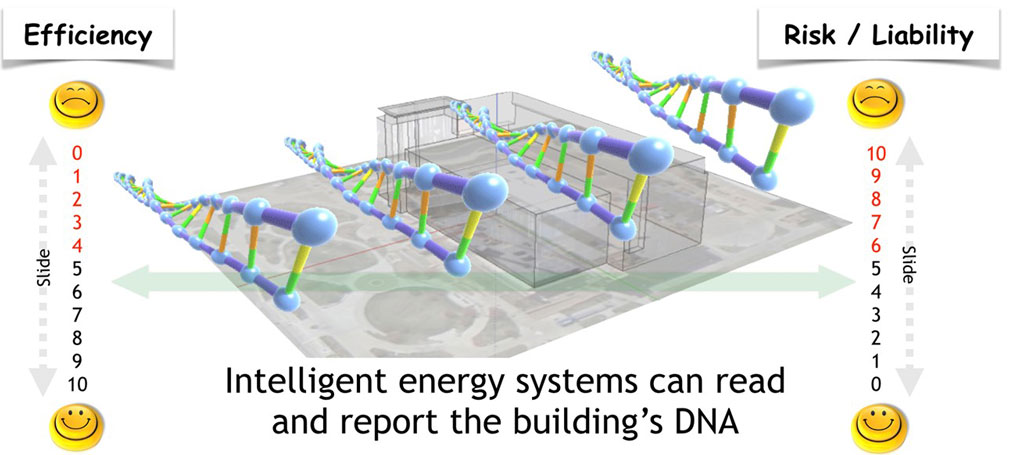

Quality assurance program specialists focus on incremental improvements in their area of practice. This is helpful and necessary, but it is only a partial toolset for the pursuit of excellence. As genomic analysis of the body’s DNA allows health care practitioners to “tweak” treatments based on predispositions, intelligent energy systems can provide genomic analysis of the organic systems and also consider factors not readily understood today such as electromagnetic sensitivity of humans and digital equipment that are bound up in the AEC infrastructure and guide the feedback loops that lead to adaptations that integratively enhance the enterprise workflow.

In this and the previous figure, the sidebars emphasize the inverse relationship between efficiency and risk/liability. As the health of the enterprise workflow improves, profits improve. Excellence is profitable! Excellence also inoculates against risk and liability, both of which thrive in an ecosystem of inefficiency and poor communication. Today, the AEC industry has the tools with which to transform itself from a seller of commodities, chasing after a continuous but disconnected stream of short-term transactions, to a trusted partner in the ongoing pursuit of excellence. Excellence builds enterprise longevity as well. This means partnering for the long run, adopting the customer’s time frame and expanding AEC’s field of vision to encompass the life of the structure: witness toll road privatization public-private partnership contracts with 50 year terms. The AEC enterprise that chooses to pursue excellence opens the door to profitable long-term relationships that raise the enterprise far above its competition and ensure both profitability and longevity.

Hi Pete,

Thank you for sharing your ideas with the world. I had no idea of your background in Quality Assurance across Africa and Europe. And of your interest in the A/E/C industry.

I’m grateful to know you via Twitter.

Kind regards,

Tara

Thanks, Tara. Delightful to meet you on Twitter, too.

pete

pete